quality egg tray moulding machine

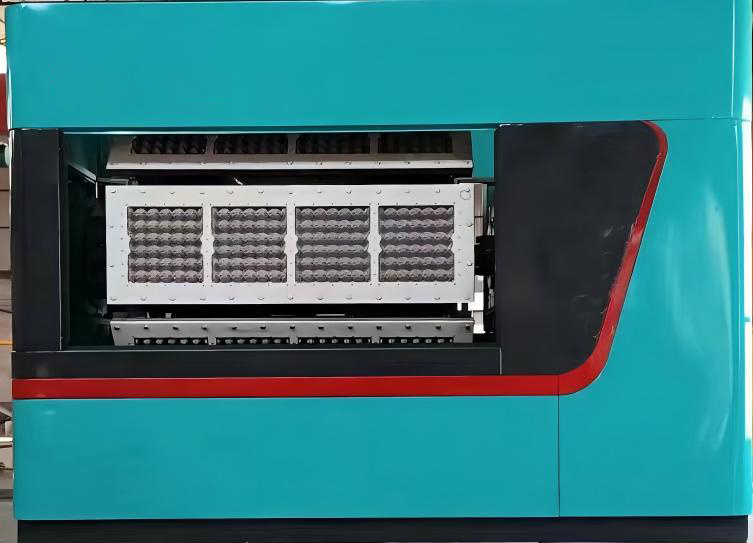

The Fully Automatic Egg Tray Moulding Machine revolutionizes egg tray production with its cutting-edge technology and seamless operation. This machine excels in converting waste paper pulp into sturdy and biodegradable egg trays, catering to the packaging needs of the poultry industry.

The 4-8 egg tray machine forms 4 egg trays per cycle with an 8-sided rotating drum, with an hourly output of 4,000-5,000 pieces. Drying options include brick kiln drying and metal multi-layer drying, with heat sources like coal, firewood, biomass pellets, natural gas, or steam. Suitable for medium-sized egg tray factories

Advantages

Compact footprint, high output, low energy consumption, and reduced labor

Workshop

50 meters long and 20 meters wide

The Fully Automatic Egg Tray Moulding Machine revolutionizes egg tray production with its cutting-edge technology and seamless operation. This machine excels in converting waste paper pulp into sturdy and biodegradable egg trays, catering to the packaging needs of the poultry industry. Its fully automated system ensures high output with minimal human intervention, making it a top choice for large-scale manufacturers.

Designed for versatility, this egg tray moulding machine supports multiple mold configurations, enabling the production of different tray types, including egg cartons and fruit trays. The advanced drying system ensures quick moisture removal, reducing production time significantly. With its energy-saving features, this machine lowers operational costs while maintaining high efficiency. It’s the perfect solution for businesses aiming to scale up their production.

Durability and performance are at the core of this egg tray moulding machine. Constructed with corrosion-resistant materials, it guarantees a long service life even in demanding environments. The intuitive control panel allows for easy adjustments, ensuring smooth operation. Additionally, the machine’s low maintenance requirements make it a practical investment for long-term use.

Investing in this egg tray moulding machine means embracing innovation and sustainability. Its automated processes, high productivity, and eco-friendly output set it apart in the market. Whether you’re a startup or an established manufacturer, this machine empowers you to meet industry standards and customer expectations effortlessly.

Related Blog

What is the production process of egg trays?

The advantages of our automatic egg tray machine

Firstly, fewer workers are needed, and machines can replace workers to complete most of the work. In addition, it can also reduce the rate of defective products.

What are the precautions for buying an egg tray machine?

Firstly, determine the required equipment specifications and models based on production needs; secondly, choose a good and experienced manufacturer to ensure the reliability of equipment quality;

quality egg tray moulding machine

The Fully Automatic Egg Tray Moulding Machine revolutionizes egg tray production with its cutting-edge technology and seamless operation. This machine excels in converting waste paper pulp into sturdy and biodegradable egg trays, catering to the packaging needs of the poultry industry.