What are the precautions for buying an egg tray machine?

Firstly, determine the required equipment specifications and models based on production needs; secondly, choose a good and experienced manufacturer to ensure the reliability of equipment quality;

What are the precautions for buying an egg tray machine?

In recent years, the demand for egg tray machines has significantly increased due to the growing awareness of sustainable packaging solutions. These machines are designed to produce egg trays from recycled paper, which not only helps in reducing waste but also provides an eco-friendly alternative for packaging eggs. However, purchasing an egg tray machine requires careful consideration and planning. In this article, we will discuss the essential precautions to take when buying an egg tray machine.

Understanding Your Production Needs

Before diving into the purchasing process, it is crucial to assess your production needs. Determine the quantity of egg trays you plan to produce daily or weekly. This assessment will help you select a machine with the appropriate capacity. Egg tray machines come in various sizes and capabilities, from small-scale models for local businesses to large industrial machines for high-volume production. Knowing your requirements will ensure that you invest in a machine that meets your specific production goals.

Researching Different Types of Machines

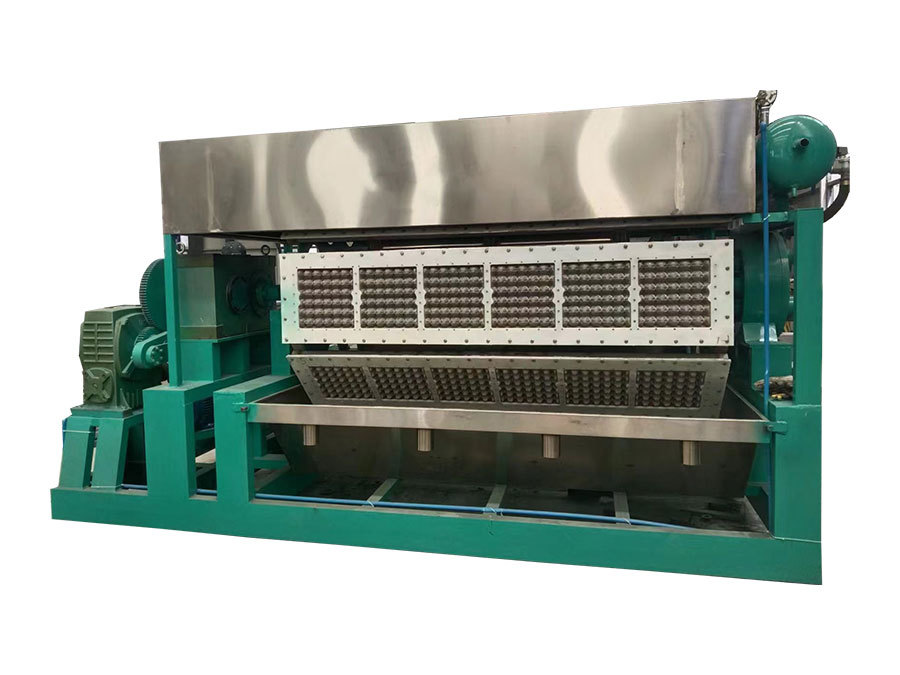

There are several types of egg tray machines available on the market, each with its unique features and specifications. Some machines are fully automated, while others require manual labor for certain processes. Fully automated machines can significantly increase production efficiency, but they may come with a higher price tag. On the other hand, semi-automated or manual machines may be more affordable but could require more labor and time. Researching the different types of machines and understanding their advantages and disadvantages will help you make an informed decision.

Evaluating Machine Quality and Durability

The quality and durability of the egg tray machine are paramount factors to consider. Investing in a high-quality machine may require a larger initial investment, but it can save you money in the long run through reduced maintenance costs and increased longevity. Look for machines made from high-quality materials, such as stainless steel or heavy-duty alloys, which can withstand the rigors of production. Additionally, read customer reviews and testimonials to gauge the machine's reliability and performance over time.

Checking for Compliance with Industry Standards

When purchasing an egg tray machine, it is essential to ensure that it complies with relevant industry standards and regulations. Different countries may have specific guidelines regarding the production of packaging materials, especially those used for food products. Ensure that the machine you are considering meets these standards to avoid any legal issues or complications in the future. Additionally, inquire about certifications that demonstrate the machine's compliance with safety and quality regulations.

Considering Energy Efficiency

Energy efficiency is another crucial aspect to consider when buying an egg tray machine. Production processes can consume a significant amount of energy, which can lead to high operational costs. Look for machines designed with energy-saving features, such as efficient heating systems and optimized production cycles. An energy-efficient machine not only reduces costs but also contributes to a more sustainable production process, aligning with the eco-friendly nature of egg trays.

Assessing the Manufacturer's Reputation

The reputation of the manufacturer is an important factor that can influence your purchasing decision. Research the manufacturer's history, experience in the industry, and customer service reputation. A reputable manufacturer is more likely to provide a reliable machine and offer good after-sales support. Look for manufacturers with positive reviews, a solid track record, and those who are willing to provide references from previous customers.

Inquiring About Technical Support and Training

When investing in an egg tray machine, it is essential to consider the level of technical support and training provided by the manufacturer. Ensure that the manufacturer offers comprehensive training for your staff on operating and maintaining the machine. Additionally, inquire about the availability of technical support in case of any issues or breakdowns. A manufacturer that provides ongoing support will help ensure smooth operations and minimize downtime.

Evaluating the Total Cost of Ownership

While the initial purchase price of the egg tray machine is a significant consideration, it is equally important to evaluate the total cost of ownership. This includes not only the purchase price but also factors such as maintenance costs, energy consumption, labor costs, and the cost of raw materials. By calculating the total cost of ownership, you can better assess the long-term financial implications of your investment and make a more informed decision.

Exploring Customization Options

Depending on your specific production needs, you may want to explore customization options for the egg tray machine. Some manufacturers offer machines that can be tailored to produce different sizes or shapes of egg trays, allowing you to meet the demands of your target market. Customization can also enhance production efficiency and reduce waste. Be sure to discuss your requirements with the manufacturer to see if they can accommodate your needs.

Conclusion

Purchasing an egg tray machine is a significant investment that requires careful consideration and planning. By taking the necessary precautions, such as understanding your production needs, researching different types of machines, evaluating quality and durability, and assessing the manufacturer's reputation, you can make a more informed decision. Additionally, considering factors such as energy efficiency, technical support, and total cost of ownership will help ensure that you choose a machine that meets your business goals and contributes to a sustainable future. With the right egg tray machine, you can successfully tap into the growing demand for eco-friendly packaging solutions while enhancing your production capabilities.

TAG:

Related Blog

What is the production process of egg trays?

The advantages of our automatic egg tray machine

Firstly, fewer workers are needed, and machines can replace workers to complete most of the work. In addition, it can also reduce the rate of defective products.

What are the precautions for buying an egg tray machine?

Firstly, determine the required equipment specifications and models based on production needs; secondly, choose a good and experienced manufacturer to ensure the reliability of equipment quality;

Exploring the Technology Behind Full-Automatic Egg Tray Machines Table of Contents 1. Introduction to Full-Automatic Egg Tray Machines 2. Overview of Egg Tray Manufacturing Technology 3. Key Components of Full-Automatic Egg Tray Machines 4. The Production Process: Step-by-Step Breakdown 5. Advantages of Using Full-Automatic Egg Tray Machines 6. Applications of Egg Tray Mac