Innovative Designs in Egg Tray Moulding Machines for Enhanced Production

Innovative Designs in Egg Tray Moulding Machines for Enhanced Production Table of Contents 1. Introduction to Egg Tray Moulding Machines 2. Importance of Egg Tray Moulding Machines in Packaging 3. Latest Design Innovations in Egg Tray Moulding Machines 4. Technological Advancements Driving Efficiency 5. Sustainability Practices in Egg Tray Production 6. Enhancing Production Efficiency

Innovative Designs in Egg Tray Moulding Machines for Enhanced Production

Table of Contents

- 1. Introduction to Egg Tray Moulding Machines

- 2. Importance of Egg Tray Moulding Machines in Packaging

- 3. Latest Design Innovations in Egg Tray Moulding Machines

- 4. Technological Advancements Driving Efficiency

- 5. Sustainability Practices in Egg Tray Production

- 6. Enhancing Production Efficiency through Innovative Designs

- 7. Case Studies: Success Stories in Egg Tray Manufacturing

- 8. Future Trends in Egg Tray Moulding Technology

- 9. FAQs about Egg Tray Moulding Machines

- 10. Conclusion

1. Introduction to Egg Tray Moulding Machines

Egg tray moulding machines play a crucial role in the packaging industry, specifically in the food sector. These machines are designed to produce biodegradable and recyclable egg trays, which are essential for protecting eggs during transport and storage. With the increasing focus on sustainable packaging solutions, the demand for high-quality egg tray moulding machines has surged, prompting manufacturers to innovate and enhance their designs.

2. Importance of Egg Tray Moulding Machines in Packaging

Egg trays serve a vital purpose in ensuring the safety of eggs, preventing breakage during transportation and storage. The **importance of egg tray moulding machines** lies not only in their ability to produce these protective trays but also in their efficiency and adaptability to modern manufacturing needs. As consumers become more environmentally conscious, the demand for sustainable packaging options continues to rise, making egg tray moulding machines a critical component in the packaging supply chain.

3. Latest Design Innovations in Egg Tray Moulding Machines

Recent innovations in egg tray moulding machine designs have focused on enhancing production speed, reducing waste, and improving overall efficiency. Key design features include:

3.1 Modular Design for Flexible Production

Modular designs allow manufacturers to customize their production lines based on demand. This flexibility enables quick adjustments to production capacity without extensive downtime.

3.2 Energy-Efficient Systems

Modern machines increasingly incorporate energy-efficient technologies, significantly lowering energy consumption during the moulding process. This not only reduces operational costs but also minimizes the environmental footprint.

3.3 User-Friendly Interfaces

Innovative user interfaces with touchscreen controls simplify the operation of egg tray moulding machines, making it easier for operators to monitor and adjust settings in real-time.

3.4 Advanced Moulding Techniques

The introduction of advanced moulding techniques, such as vacuum forming and pressure moulding, has improved the quality and consistency of egg trays. These techniques ensure that each tray meets strict quality standards.

4. Technological Advancements Driving Efficiency

Technological advancements are at the forefront of enhancing the efficiency of egg tray moulding machines. The integration of automation and smart technologies is transforming the production landscape.

4.1 Automation in Egg Tray Production

Automation minimizes manual intervention, leading to faster production rates and reduced labor costs. Automated systems can handle everything from pulp preparation to tray packing, ensuring consistent output.

4.2 IoT and Smart Manufacturing

The Internet of Things (IoT) technology allows for real-time monitoring and data collection throughout the production process. This data can be analyzed to optimize machine performance and predict maintenance needs.

4.3 Predictive Maintenance

With advancements in sensor technology, predictive maintenance has become a reality in egg tray moulding machines. By anticipating equipment failures before they occur, manufacturers can avoid costly downtimes and enhance productivity.

5. Sustainability Practices in Egg Tray Production

Sustainability is a key consideration in the design and operation of egg tray moulding machines. Manufacturers are increasingly adopting practices that minimize waste and promote eco-friendly production methods.

5.1 Use of Recycled Raw Materials

Many egg tray moulding machines now utilize recycled paper and cardboard as raw materials. This practice not only reduces waste but also lowers production costs.

5.2 Water Conservation Techniques

Innovative water conservation techniques are being implemented to minimize water usage during the pulp preparation process. Closed-loop systems recirculate water, reducing overall consumption.

5.3 Energy Recovery Systems

Energy recovery systems capture and reuse energy generated during the production process, further enhancing the sustainability of egg tray manufacturing.

6. Enhancing Production Efficiency through Innovative Designs

The efficiency of egg tray production can be significantly improved through innovative designs and the adoption of best practices.

6.1 Streamlined Production Processes

By analyzing and streamlining each stage of the production process, manufacturers can identify bottlenecks and implement solutions that enhance overall efficiency.

6.2 Quality Control Systems

Incorporating robust quality control systems ensures that each egg tray produced meets the highest standards. This reduces waste and rework, ultimately leading to more efficient operations.

6.3 Training and Development Programs

Investing in training programs for operators and technicians ensures that personnel are well-equipped to utilize the latest technologies effectively, further enhancing production efficiency.

7. Case Studies: Success Stories in Egg Tray Manufacturing

Examining successful case studies provides valuable insights into the practical applications of innovative designs in egg tray moulding machines.

7.1 Case Study: GreenPack Solutions

GreenPack Solutions implemented a modular egg tray production system that increased their output by 35% within six months. By utilizing energy-efficient technologies and automating their processes, they significantly reduced operational costs.

7.2 Case Study: EcoEgg Trays Inc.

EcoEgg Trays Inc. focused on sustainability by using 100% recycled materials in their production. Their commitment to eco-friendly practices helped them capture a larger market share and improve their brand reputation.

8. Future Trends in Egg Tray Moulding Technology

As the packaging industry evolves, several trends are expected to shape the future of egg tray moulding technology.

8.1 Customization and Personalization

The demand for customized packaging solutions is on the rise. Future egg tray moulding machines may incorporate advanced capabilities for creating unique designs tailored to specific client needs.

8.2 Enhanced Automation

Continued advancements in automation will likely lead to smarter, more adaptable production systems capable of handling varying production volumes with ease.

8.3 Integration with E-Commerce Logistics

As e-commerce grows, egg tray moulding machines may increasingly integrate with logistics solutions, ensuring that packaging can be efficiently handled throughout the supply chain.

9. FAQs about Egg Tray Moulding Machines

9.1 What materials are used in egg tray production?

Egg trays are primarily made from recycled paper and cardboard, which are processed into pulp before being moulded into trays.

9.2 How long does it take to produce egg trays?

The production time can vary depending on the machine's capacity and the complexity of the design, but modern machines can produce thousands of trays in a single hour.

9.3 Are egg trays biodegradable?

Yes, most egg trays made from recycled paper and cardboard are biodegradable, making them an environmentally friendly packaging option.

9.4 What are the maintenance requirements for egg tray moulding machines?

Regular maintenance including cleaning, lubrication, and inspections is essential to ensure optimal performance and longevity of egg tray moulding machines.

9.5 How can I choose the right egg tray moulding machine for my business?

Consider factors such as production volume, energy efficiency, customization options, and ease of use when selecting an egg tray moulding machine for your business.

10. Conclusion

In conclusion, the evolution of egg tray moulding machines reflects the industry's response to the growing demand for innovative, efficient, and sustainable packaging solutions. With advancements in design and technology, manufacturers can enhance production capabilities while meeting consumer expectations for quality and environmental responsibility. As the market for eco-friendly packaging continues to expand, investing in state-of-the-art egg tray moulding machines will be essential for businesses looking to thrive in this competitive landscape. Embracing innovation today will pave the way for a more sustainable and efficient future in egg tray production.

Previous

Next

Previous:

Next:

Related Blog

What is the production process of egg trays?

The advantages of our automatic egg tray machine

Firstly, fewer workers are needed, and machines can replace workers to complete most of the work. In addition, it can also reduce the rate of defective products.

What are the precautions for buying an egg tray machine?

Firstly, determine the required equipment specifications and models based on production needs; secondly, choose a good and experienced manufacturer to ensure the reliability of equipment quality;

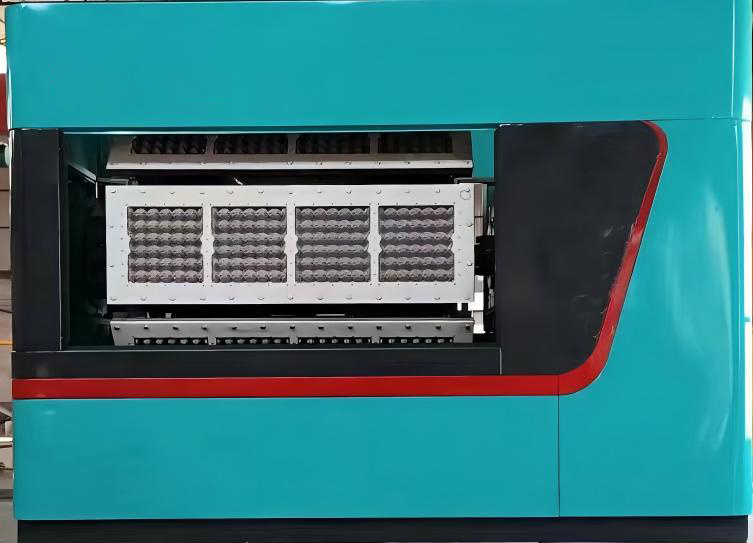

quality egg tray moulding machine

The Fully Automatic Egg Tray Moulding Machine revolutionizes egg tray production with its cutting-edge technology and seamless operation. This machine excels in converting waste paper pulp into sturdy and biodegradable egg trays, catering to the packaging needs of the poultry industry.