Revolutionizing Production: Discover the Benefits of Full-Automatic Egg Tray Machines

Revolutionizing Production: Discover the Benefits of Full-Automatic Egg Tray Machines In today's fast-paced industrial landscape, efficiency and innovation are paramount. One such revolutionary advancement in the manufacturing sector is the full-automatic egg tray machine. This state-of-the-art equipment not only streamlines production processes but also enhances the quality of the final product.

Revolutionizing Production: Discover the Benefits of Full-Automatic Egg Tray Machines

In today's fast-paced industrial landscape, efficiency and innovation are paramount. One such revolutionary advancement in the manufacturing sector is the full-automatic egg tray machine. This state-of-the-art equipment not only streamlines production processes but also enhances the quality of the final product. In this comprehensive guide, we will delve into the myriad benefits of full-automatic egg tray machines, exploring how they transform the paper processing industry while contributing to sustainability and cost-effectiveness.

Table of Contents

- Understanding Egg Tray Machines

- What is a Full-Automatic Egg Tray Machine?

- Benefits of Using Full-Automatic Egg Tray Machines

- Enhanced Efficiency and Productivity

- Improved Quality and Consistency

- Cost Effectiveness

- Environmental Sustainability

- Components of Full-Automatic Egg Tray Machines

- How Full-Automatic Egg Tray Machines Work

- Applications of Egg Trays in Various Industries

- Choosing the Right Full-Automatic Egg Tray Machine

- FAQs About Full-Automatic Egg Tray Machines

Understanding Egg Tray Machines

Egg tray machines play a crucial role in the production of packaging solutions. They are designed to create molded pulp products, primarily egg trays, from recycled paper materials. These machines contribute significantly to sustainable manufacturing practices by promoting the recycling of paper waste into valuable products. As industries shift towards eco-friendliness, understanding the mechanics and benefits of these machines is vital.

What is a Full-Automatic Egg Tray Machine?

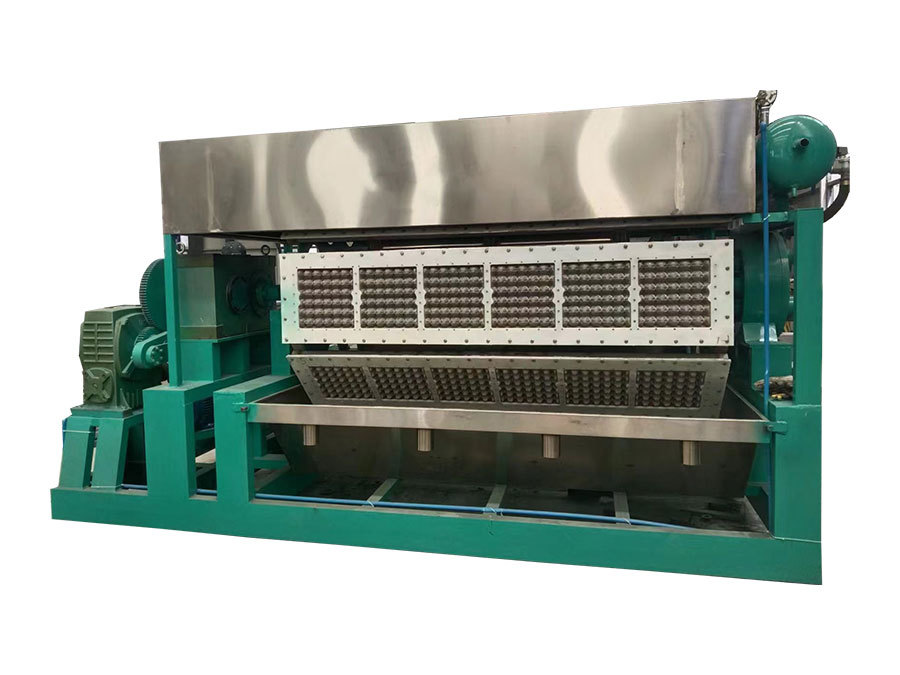

A full-automatic egg tray machine is a sophisticated piece of equipment that automates the entire production process of egg trays. From pulp preparation to drying and packaging, this machine integrates various technological advancements, ensuring a seamless workflow. With advanced features such as PLC control, automatic feeding, and a multi-functional drying system, these machines significantly enhance productivity and reduce labor costs.

Benefits of Using Full-Automatic Egg Tray Machines

Enhanced Efficiency and Productivity

One of the primary advantages of full-automatic egg tray machines is the enhanced efficiency they bring to the production process. These machines operate at high speeds, capable of producing thousands of egg trays in a single day. By minimizing manual labor and automating tasks such as pulp mixing, molding, and drying, manufacturers can achieve higher output levels while maintaining consistent quality. This efficiency not only meets market demand but also positions companies competitively within the industry.

Improved Quality and Consistency

Quality assurance is vital in any manufacturing process, and full-automatic egg tray machines excel in delivering uniform products. The automated nature of these machines ensures precise control over every step of production, from pulp density to drying time. This accuracy results in egg trays that are consistently sturdy and reliable, meeting the rigorous standards of the agricultural and food packaging sectors. Manufacturers can confidently provide products that adhere to quality expectations, thereby enhancing brand reputation.

Cost Effectiveness

Investing in a full-automatic egg tray machine can lead to significant cost savings for manufacturers. Although the initial investment may seem substantial, the long-term benefits far outweigh the costs. With reduced labor requirements and optimized energy consumption, businesses can lower operational costs significantly. Furthermore, the efficient use of recycled materials minimizes raw material expenses, allowing companies to maximize profit margins while maintaining competitive pricing.

Environmental Sustainability

In an era where sustainability is at the forefront of industrial practices, full-automatic egg tray machines contribute immensely to ecological balance. By utilizing recycled paper waste, these machines help reduce landfill contributions and promote the circular economy. Additionally, many machines are designed with energy efficiency in mind, further minimizing their environmental impact. Manufacturers embracing this technology not only enhance their corporate social responsibility but also appeal to environmentally-conscious consumers.

Components of Full-Automatic Egg Tray Machines

Understanding the components of full-automatic egg tray machines can provide valuable insights into their operation and maintenance. Key components include:

- Pulping System: This system prepares the recycled paper into pulp, ensuring optimal consistency for molding.

- Molding Machine: The heart of the operation, this machine shapes the pulp into egg trays through a precise molding process.

- Drying System: Essential for removing moisture, the drying system can be either an industrial dryer or a natural drying system, depending on the design.

- Transport System: Automated conveyors transport trays through various stages of production, ensuring a smooth workflow.

- Control System: A PLC (Programmable Logic Controller) manages the entire operation, allowing for easy monitoring and adjustments.

How Full-Automatic Egg Tray Machines Work

The operation of a full-automatic egg tray machine is a well-coordinated process that involves several stages:

- Pulp Preparation: Waste paper is fed into the pulping system, where it's mixed with water and processed into a slurry.

- Molding: The pulp slurry is transferred to the molding machine, where it is shaped into the desired egg tray form using molds.

- Drying: The molded trays are then dried either through heat or in natural sunlight, removing excess moisture.

- Packaging: Once dried, the trays are stacked and transported to the packaging area for distribution.

- Quality Control: Throughout the process, quality checks are in place to ensure that the final product meets industry standards.

Applications of Egg Trays in Various Industries

Egg trays produced by full-automatic machines are utilized across various sectors. Key applications include:

- Agriculture: Egg trays provide safe transportation and storage for eggs, preventing damage during handling.

- Food Packaging: Manufacturers use egg trays for packaging fruits, vegetables, and other delicate items, ensuring they remain intact.

- Consumer Products: Egg trays are also employed in providing cushioning for various electronic and fragile items during shipping.

- Environmental Solutions: With their eco-friendly nature, these trays are increasingly used in sustainable packaging initiatives.

Choosing the Right Full-Automatic Egg Tray Machine

Selecting the right full-automatic egg tray machine is crucial for maximizing production efficiency. Consider the following factors:

- Production Capacity: Assess your production needs and choose a machine that can meet those requirements without compromising quality.

- Energy Efficiency: Look for machines designed to minimize energy consumption, as this can lead to significant cost savings.

- Technology Integration: Opt for machines that feature advanced technology for ease of operation and maintenance.

- Supplier Reputation: Research manufacturers with a proven track record for reliability and customer service.

FAQs About Full-Automatic Egg Tray Machines

What materials are used in producing egg trays?

Egg trays are primarily made from recycled paper, cardboard, and other biodegradable materials. These materials are processed into pulp to create the final product.

How long does it take to produce egg trays using a full-automatic machine?

The production time varies based on the machine's capacity, but a full-automatic egg tray machine can produce thousands of trays within a few hours.

Are full-automatic egg tray machines environmentally friendly?

Yes, these machines contribute to environmental sustainability by recycling paper waste and minimizing energy consumption during production.

What is the maintenance required for these machines?

Routine maintenance includes cleaning, lubrication, and periodic inspections to ensure all components are functioning efficiently.

Can I customize the production capacity of the machine?

Many manufacturers offer customizable solutions, allowing you to choose the machine's specifications based on your production needs.

Conclusion

In conclusion, full-automatic egg tray machines represent a significant advancement in the manufacturing of packaging solutions. Their ability to enhance efficiency, improve product quality, cut costs, and promote environmental sustainability makes them an invaluable asset in the paper processing industry. As businesses increasingly focus on eco-friendly practices and operational efficiency, investing in full-automatic egg tray machines will not only meet market demands but also position manufacturers for future success. With the right machinery in place, the potential for growth and innovation in the packaging sector is limitless.

TAG:

Related Blog

What is the production process of egg trays?

The advantages of our automatic egg tray machine

Firstly, fewer workers are needed, and machines can replace workers to complete most of the work. In addition, it can also reduce the rate of defective products.

What are the precautions for buying an egg tray machine?

Firstly, determine the required equipment specifications and models based on production needs; secondly, choose a good and experienced manufacturer to ensure the reliability of equipment quality;

Revolutionizing Production: Discover the Benefits of Full-Automatic Egg Tray Machines

Revolutionizing Production: Discover the Benefits of Full-Automatic Egg Tray Machines In today's fast-paced industrial landscape, efficiency and innovation are paramount. One such revolutionary advancement in the manufacturing sector is the full-automatic egg tray machine. This state-of-the-art equipment not only streamlines production processes but also enhances the quality of the final product.