Unlocking Efficiency: The Benefits of Using a Pulp Egg Tray Making Machine for Sustainable Production

Unlocking Efficiency: The Benefits of Using a Pulp Egg Tray Making Machine Table of Contents 1. Introduction to Pulp Egg Tray Making Machines 2. Understanding Pulp Egg Tray Making 3. Benefits of Pulp Egg Tray Making Machines 3.1 Eco-Friendly Manufacturing 3.2 Cost-Effectiveness 3.3 High Productivity 4. The Technology Behin

Unlocking Efficiency: The Benefits of Using a Pulp Egg Tray Making Machine

Table of Contents

- 1. Introduction to Pulp Egg Tray Making Machines

- 2. Understanding Pulp Egg Tray Making

- 3. Benefits of Pulp Egg Tray Making Machines

- 4. The Technology Behind Pulp Egg Tray Machines

- 5. Applications of Pulp Egg Tray Machines

- 6. Choosing the Right Pulp Egg Tray Machine

- 7. Maintaining Your Pulp Egg Tray Machine

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to Pulp Egg Tray Making Machines

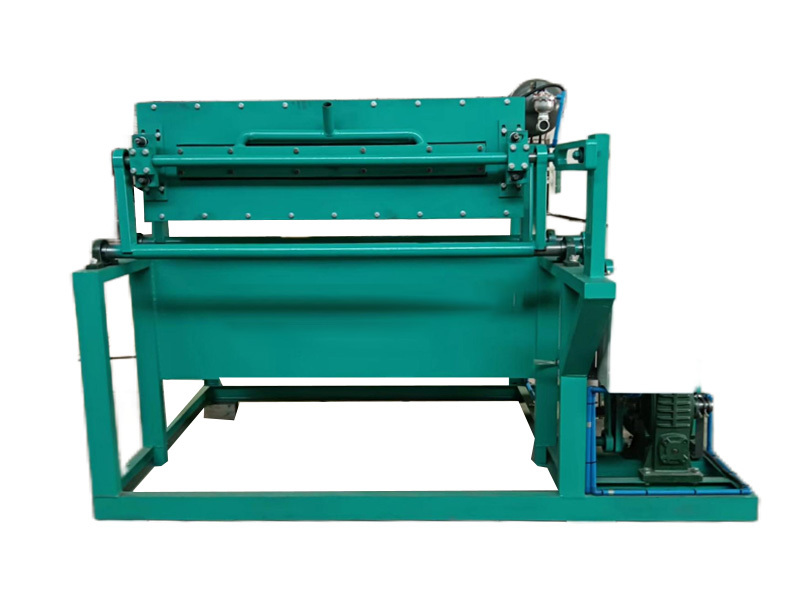

In today's manufacturing landscape, the push for sustainability and efficiency has never been stronger. Among the various solutions, the **pulp egg tray making machine** stands out as a powerful tool for manufacturers seeking to enhance their production processes. This innovative machinery not only helps in the production of egg trays but also contributes to environmental sustainability by recycling waste paper into valuable products.

2. Understanding Pulp Egg Tray Making

The process of making pulp egg trays involves several steps, beginning with sourcing raw materials, typically recycled paper products. The paper is then processed to create a slurry that is shaped into trays using specialized molds. After drying, these trays are ready for use, primarily in the agricultural and food industries. This seamless process allows for the efficient production of durable and eco-friendly packaging.

3. Benefits of Pulp Egg Tray Making Machines

Utilizing a pulp egg tray making machine offers numerous advantages, making it an attractive investment for businesses in the manufacturing sector.

3.1 Eco-Friendly Manufacturing

One of the most significant benefits of using pulp egg tray making machines is their contribution to eco-friendly manufacturing. These machines turn waste paper into usable products, thus reducing landfill waste and promoting recycling. By adopting this technology, companies can align themselves with sustainable practices, appealing to environmentally conscious consumers.

3.2 Cost-Effectiveness

Investing in a pulp egg tray making machine is not only an eco-friendly choice but also a cost-effective one. These machines typically have low operational costs due to their efficient use of energy and materials. Moreover, the ability to source raw materials at a low cost (recycled paper) significantly lowers production expenses. Consequently, manufacturers can enjoy higher profit margins and improved return on investment.

3.3 High Productivity

Pulp egg tray making machines are designed to maximize productivity. With the ability to produce thousands of trays per hour, these machines streamline the manufacturing process, ensuring that businesses can meet high demand levels without sacrificing quality. Automation features further enhance efficiency, allowing for continuous production with minimal downtime.

4. The Technology Behind Pulp Egg Tray Machines

Modern pulp egg tray making machines incorporate advanced technology to optimize the manufacturing process. Key technological features include:

- **Hydraulic forming systems** that ensure consistent shaping of trays.

- **Energy-efficient drying systems** that reduce energy consumption while maintaining high-quality output.

- **Automated control systems** that monitor production parameters, enabling quick adjustments to enhance performance.

These technological advancements not only improve the quality of the final product but also reduce overall production costs.

5. Applications of Pulp Egg Tray Machines

Pulp egg tray making machines have diverse applications beyond egg packaging. They are used in various sectors, including:

- **Agriculture:** For packaging eggs, fruits, and vegetables, ensuring protection during transport.

- **Electronics:** To provide cushioning for fragile electronic components.

- **Cosmetics and Pharmaceuticals:** For packaging products that require careful handling.

This versatility underscores the machine's value in different industries, making them a critical investment for manufacturers.

6. Choosing the Right Pulp Egg Tray Machine

Selecting the right pulp egg tray making machine is crucial for maximizing productivity and efficiency. When considering options, keep the following factors in mind:

6.1 Key Features to Consider

- **Production Capacity:** Assess the machine's output capacity to ensure it meets your production needs.

- **Material Compatibility:** Ensure the machine can efficiently process the type of raw materials you plan to use.

- **Automation Level:** Consider whether you want a fully automatic system or manual operation, depending on your budget and workforce.

6.2 Supplier Recommendations

Research reputable suppliers who specialize in pulp egg tray making machines. Look for vendors with positive reviews and proven track records. It's advisable to request demos and product specifications to make an informed decision.

7. Maintaining Your Pulp Egg Tray Machine

Regular maintenance of pulp egg tray machines is essential for ensuring longevity and optimal performance. Key maintenance practices include:

- **Routine Cleaning:** Regularly clean the machine to prevent paper debris build-up, which can hinder operations.

- **Lubrication:** Apply appropriate lubricants to moving parts to reduce wear and tear.

- **Periodic Inspections:** Conduct inspections to identify any signs of wear, allowing for timely repairs that prevent downtime.

Implementing a comprehensive maintenance schedule can significantly extend the lifespan of your machinery.

8. Frequently Asked Questions

What raw materials can be used in a pulp egg tray making machine?

You can primarily use recycled paper, cardboard, and other paper-based materials to create pulp for egg trays.

How long does it take to produce egg trays using this machine?

Production time varies based on the machine’s capacity, but high-efficiency models can produce thousands of trays per hour.

Are pulp egg tray making machines energy-efficient?

Yes, modern machines are designed to be energy-efficient, significantly reducing operational costs while maintaining high productivity levels.

Can these machines be used for products other than egg trays?

Absolutely! They are versatile and can be adapted to produce trays for fruits, vegetables, and electronics, among others.

What is the average lifespan of a pulp egg tray making machine?

With proper maintenance, a pulp egg tray making machine can last several years, typically ranging from 5 to 10 years or longer.

9. Conclusion

Investing in a **pulp egg tray making machine** offers manufacturers a pathway to enhanced efficiency, sustainability, and profitability. By streamlining production processes and minimizing waste, these machines not only contribute to a healthier planet but also create robust business opportunities. As industries continue to seek eco-friendly solutions, the pulp egg tray making machine stands as a testament to innovation in manufacturing, ensuring companies remain competitive in a rapidly evolving marketplace.

TAG:

Previous

Related Blog

What is the production process of egg trays?

The advantages of our automatic egg tray machine

Firstly, fewer workers are needed, and machines can replace workers to complete most of the work. In addition, it can also reduce the rate of defective products.

What are the precautions for buying an egg tray machine?

Firstly, determine the required equipment specifications and models based on production needs; secondly, choose a good and experienced manufacturer to ensure the reliability of equipment quality;

Unlocking Efficiency: The Benefits of Using a Pulp Egg Tray Making Machine Table of Contents 1. Introduction to Pulp Egg Tray Making Machines 2. Understanding Pulp Egg Tray Making 3. Benefits of Pulp Egg Tray Making Machines 3.1 Eco-Friendly Manufacturing 3.2 Cost-Effectiveness 3.3 High Productivity 4. The Technology Behin