Automatic quantitative packaging of refractory materials

Heat-resistant coating: Add silicon-aluminum ceramic fibers (accounting for 15%-20%) to the pulp. The heat resistance is enhanced to 1600℃ (while traditional paper supports can only withstand 180℃). The newly baked refractory bricks (with a temperature of approximately 1200℃) are directly packaged without any deformation or combustion.

Solved issues

1、Extreme heat tolerance

Heat-resistant coating: Add silicon-aluminum ceramic fibers (accounting for 15%-20%) to the pulp. The heat resistance is enhanced to 1600℃ (while traditional paper supports can only withstand 180℃). The newly baked refractory bricks (with a temperature of approximately 1200℃) are directly packaged without any deformation or combustion.

Heat radiation shielding: Surface composite aluminum foil reflective layer, reduces heat conduction rate, protects peripheral logistics equipment.

2. Resistance to Abrasion and Compression Damage

Surface hardening treatment: Utilizing a nano-silicon carbide coating (with a hardness of HV 2200), the wear resistance is enhanced by 8 times compared to ordinary trays, and it can withstand the friction caused by sharp edges of refractory materials.

Load-bearing structure optimization: Honeycomb-shaped three-dimensional rib plate design, single support can bear a load of 1.5 tons (size: 1200×800×200mm), compressive strength of 35 MPa.

3. Precise Quantification and Moisture Prevention

Dynamic weighing filling: Integrates a high-precision belt scale (error ≤ 0.3%), automatically adjusts the filling volume for different densities of refractory particles (such as alumina, silicon carbide).

Moisture-proof sealing process: The surface is coated with hydrophobic nano-SiO₂, with the moisture content controlled at ≤ 0.5%, preventing the deterioration of material properties due to moisture absorption.

4. Automated and efficient operations

Mechanical arm collaboration: High-temperature-resistant robotic arm (with ceramic joint protection) for automatic stacking, completing the stacking of 1 ton of goods in 10 minutes, reducing manual labor by 80%.

Intelligent logistics connection: The pallet is embedded with a heat-resistant RFID chip (with a maximum operating temperature of 800℃), and automatically connects to the kiln's discharge system.

Applicable scenarios

- Fire-resistant bricks (alumina type), casting materials (granular), fire-resistant fiber cotton, fine powder fire-resistant coatings.

TAG:

Previous

Previous:

Related Blog

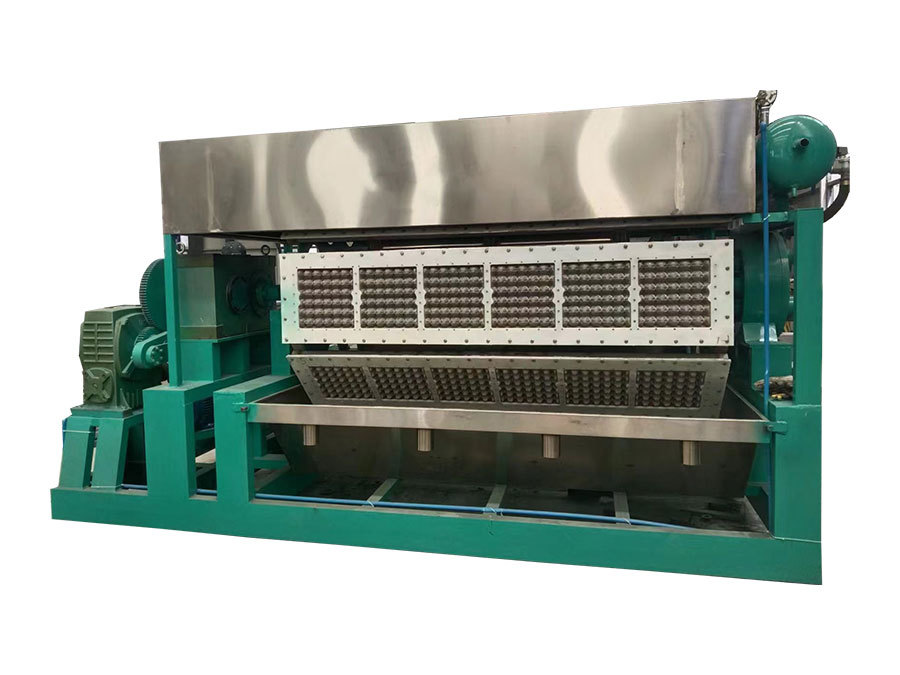

What is the production process of egg trays?

The advantages of our automatic egg tray machine

Firstly, fewer workers are needed, and machines can replace workers to complete most of the work. In addition, it can also reduce the rate of defective products.

What are the precautions for buying an egg tray machine?

Firstly, determine the required equipment specifications and models based on production needs; secondly, choose a good and experienced manufacturer to ensure the reliability of equipment quality;

Exploring the Technology Behind Full-Automatic Egg Tray Machines Table of Contents 1. Introduction to Full-Automatic Egg Tray Machines 2. Overview of Egg Tray Manufacturing Technology 3. Key Components of Full-Automatic Egg Tray Machines 4. The Production Process: Step-by-Step Breakdown 5. Advantages of Using Full-Automatic Egg Tray Machines 6. Applications of Egg Tray Mac