Automatic quantitative packaging of crops

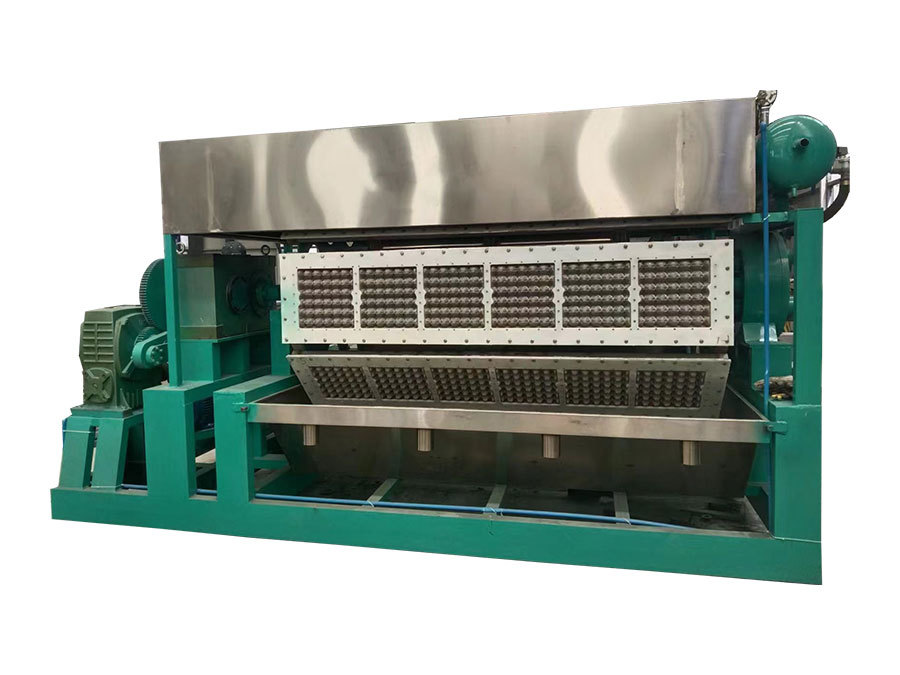

The egg tray machine can produce different-sized recessed trays (such as fruit trays and bottle trays) by changing the molds. Each recess has a fixed capacity, enabling the automatic and quantitative packaging of agricultural products.

Solved issues

1、Precise quantification and standardized packaging

The egg tray machine can produce different-sized recessed trays (such as fruit trays and bottle trays) by changing the molds. Each recess has a fixed capacity, enabling the automatic and quantitative packaging of agricultural products. For example, each slot of the apple tray can hold 1 apple, and each slot of the coffee tray is fixed to hold 4 cups. There is no need for manual measurement, and the error rate is less than 5%.

2. Reduce transportation losses

The pulp molded pallets feature a shock-absorbing and earthquake-resistant structure, which can effectively protect fragile crops (such as fruits and berries) from being crushed during transportation. Compared to traditional loose packaging or plastic packaging, the damage rate is reduced by more than 30%.

3. Using eco-friendly materials instead of plastic

Using waste paper (such as old newspapers, cardboard boxes, etc.) as raw materials, the production process does not involve the addition of plastic, and the products can be naturally decomposed. This solves the pollution problem caused by plastic foam packaging and conforms to the trend of green packaging for agricultural products.

4. Enhance packaging efficiency

The fully automatic production line (such as the ET6000 model) can produce 6,000 pallets per hour. When combined with the stacking and sorting system, it can automatically complete sorting, counting and palletizing, with an efficiency that is 8 to 10 times higher than manual packaging.

5. Adapt to diverse demands

By adjusting the slurry concentration (concentration adjustment system) and adding waterproofing agents (fully automatic additive system), moisture-proof and pressure-resistant packaging can be produced, meeting the special requirements of water-containing crops such as fruits and vegetables.

Applicable scenarios

Small fruit packaging, beverage container fixation, bottled agricultural product packaging, fresh food e-commerce logistics

TAG:

Next

Previous:

Next:

Related Blog

What is the production process of egg trays?

The advantages of our automatic egg tray machine

Firstly, fewer workers are needed, and machines can replace workers to complete most of the work. In addition, it can also reduce the rate of defective products.

What are the precautions for buying an egg tray machine?

Firstly, determine the required equipment specifications and models based on production needs; secondly, choose a good and experienced manufacturer to ensure the reliability of equipment quality;

Exploring the Technology Behind Full-Automatic Egg Tray Machines Table of Contents 1. Introduction to Full-Automatic Egg Tray Machines 2. Overview of Egg Tray Manufacturing Technology 3. Key Components of Full-Automatic Egg Tray Machines 4. The Production Process: Step-by-Step Breakdown 5. Advantages of Using Full-Automatic Egg Tray Machines 6. Applications of Egg Tray Mac