The 3-1Integrated egg tray machine is suitable for small-scale family workshops, with an hourly output of about 1,000 pieces. The drying method can be air drying. The drying area covers about 2,00 square meters, and the production area covers about 50 square meters. The formed egg trays are placed on trays (bamboo or galvanized) and then on drying racks, pushed to open spaces, where they are dried by sunlight and natural wind—this is the air drying process.

Generally, 100-200 racks are needed, with each rack holding 24-30 mesh sheets. Each mesh sheet can hold 3 egg trays.

Discover the future of sustainable packaging with our advanced pulp egg tray making machine. This innovative equipment is engineered to transform recycled paper into high-quality, protective egg trays efficiently and reliably. By utilizing a fully automated process, our pulp egg tray making machine ensures consistent output, making it an indispensable asset for modern poultry farms and packaging businesses. Embrace an eco-friendly solution that turns waste into valuable, market-ready products.

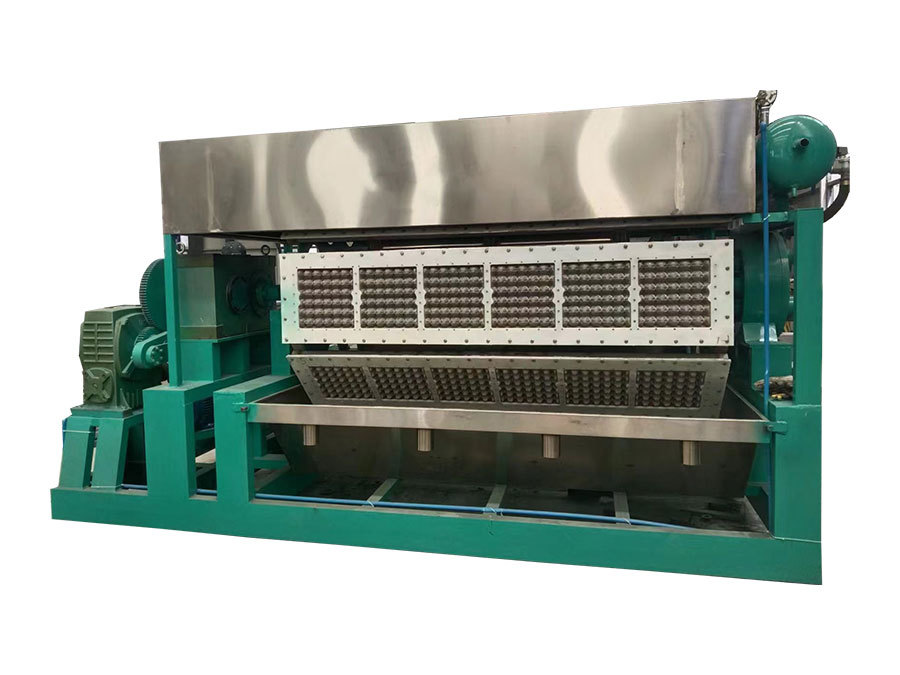

The core of our pulp egg tray making machine lies in its robust and intelligent manufacturing process. It seamlessly integrates pulping, molding, drying, and pressing stages. The system automatically proportions pulp and water, creating a uniform mixture that is then precisely shaped into durable egg trays. This streamlined workflow guarantees high productivity and minimizes manual intervention, ensuring your operation runs smoothly around the clock.

We understand that efficiency is key to your profitability. Therefore, our pulp egg tray making machine is designed for exceptional performance and low operational costs. It is highly energy-efficient, significantly reducing power consumption during the drying phase. Furthermore, its versatility allows you to produce various tray designs and sizes by simply changing the mold, providing the flexibility to meet diverse market demands and maximize your return on investment.

Durability and minimal maintenance are hallmarks of our machinery. Constructed from high-grade, corrosion-resistant materials, this pulp egg tray making machine is built to withstand rigorous, continuous use. Our comprehensive after-sales support, including installation guidance and technical assistance, ensures you get the most out of your equipment. Investing in our machine means securing a long-term, profitable, and sustainable packaging production line for your business.

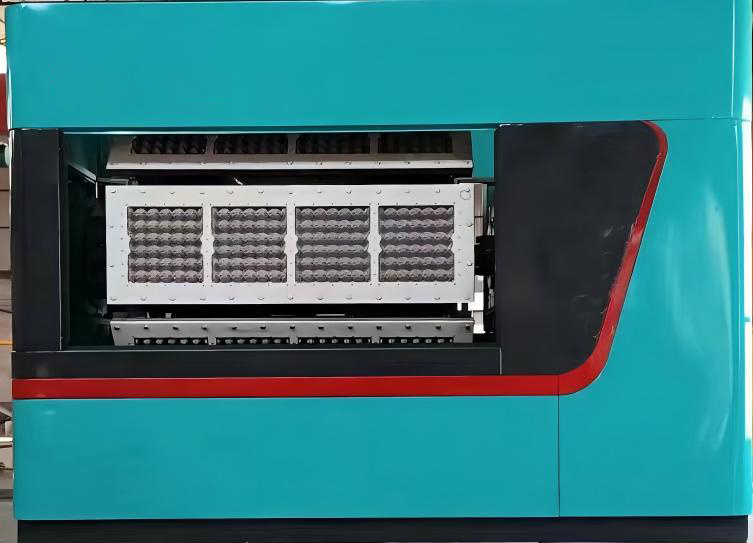

Factory scene

FAQ

What are the main products of our company?

Zhengzhou Miqi Machinery Equipment Co., Ltd. has a professional R&D team dedicated to the research and innovation of egg tray machines, egg tray production lines, pulp molding production lines, industrial packaging, tableware packaging, and automatic packaging machines. With years of theoretical and practical experience, we provide customers with comprehensive after-sales service.

Packaging system

The dried egg trays are sent through an automatic collection machine, counted, then compressed by a packaging machine, and finally packaged onto trays. This results in space savings and improved transportation convenience.

Metal drying system

The drying cabinet is linked to the molding machine. The wet trays are transferred to the drying cabinet for drying. The insulation layer is made of high-density mineral insulation cotton. The drying room has six layers, and the drying time is approximately 17-18 minutes. The uniquely designed circulating fan and automatic dehumidification system drive the hot air to circulate, removing moisture and drying the trays. This not only improves the drying efficiency but also reduces labor costs.

Brick kiln drying

The brick drying kiln has only one layer and is 60-80 meters long. The length may vary depending on the production volume. The formed egg trays are conveyed into the kiln through a mesh belt. The temperature should be controlled between 180-220 degrees. After about 20 minutes, the egg trays come out dry.

3-1Integrated egg tray machine

Category:

TAG:

new pulp egg tray making machine

Get A Quote

Note: Please leave your contact information and our professionals will contact you as soon as possible!