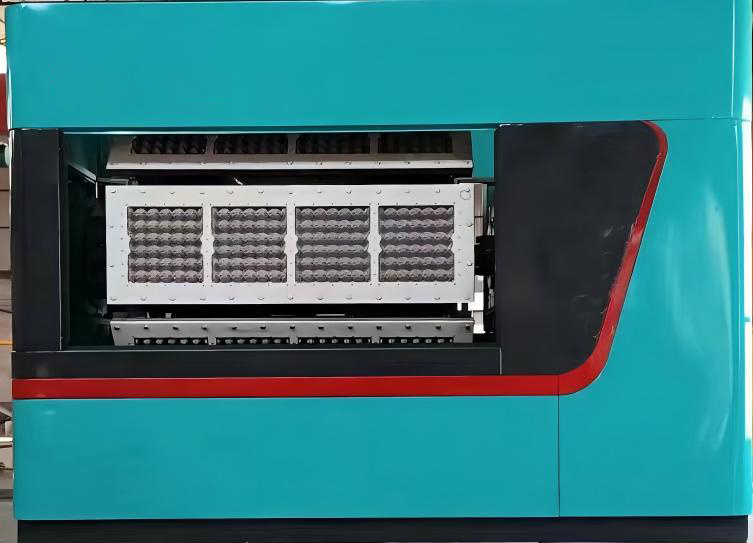

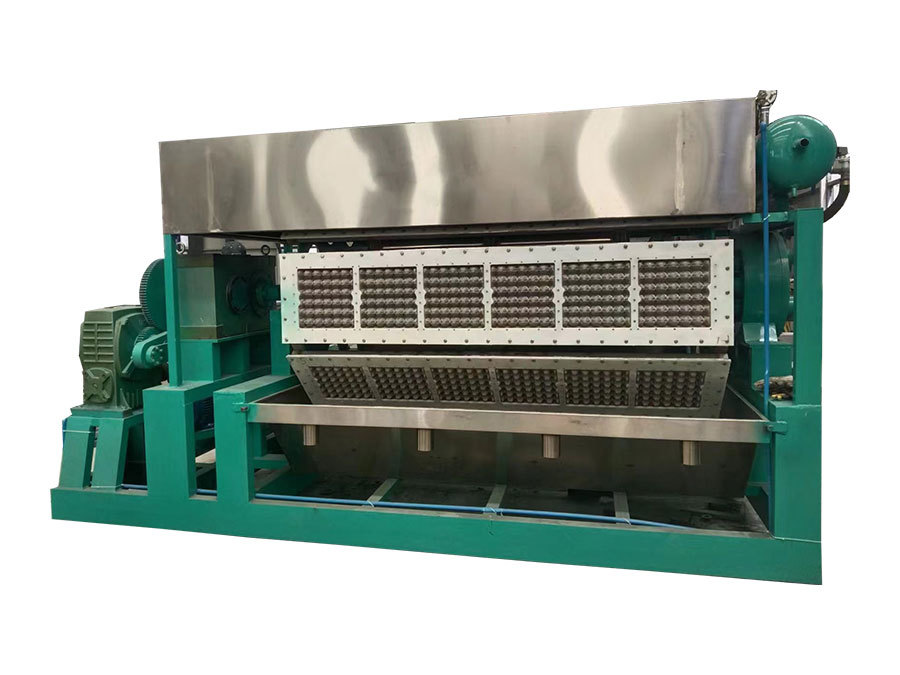

The 6-8 egg tray machine forms 6 egg trays per cycle with 8-sided rotating drum, with an hourly output of 6,000-7,000 pieces. Drying options include brick kiln drying and metal multi-layer drying, with energy sources like coal, firewood, biomass pellets, natural gas, or steam. Suitable for large-scale egg tray factory investment

Advantages

Compact footprint, high output, low energy consumption, and reduced labor

Workshop

55 meters long and 25 meters wide

The Paper Pulp Egg Tray Making Machine is an advanced piece of equipment designed to transform waste paper into high-quality egg trays and packaging products. By utilizing recycled paper pulp as raw material, this machine promotes eco-friendly production while delivering durable and protective trays. The Paper Pulp Egg Tray Making Machine is widely used in poultry farms, packaging industries, and recycling businesses that require sustainable packaging solutions.

One of the key advantages of the Paper Pulp Egg Tray Making Machine is its ability to produce various tray designs. It can be adapted to manufacture egg cartons, fruit trays, coffee cup holders, and other molded pulp products. With efficient molding and drying systems, it ensures consistent tray quality, reduced production time, and minimal waste, making it suitable for both small and large-scale operations.

Engineered with robust materials and modern technology, the Paper Pulp Egg Tray Making Machine provides stable performance, long service life, and low maintenance requirements. Its automated operation helps reduce manual labor while maximizing productivity. Operators can easily control the machine, ensuring smooth production with minimal technical expertise.

Environmentally friendly and energy-efficient, the Paper Pulp Egg Tray Making Machine contributes to recycling efforts and reduces dependence on plastic packaging. By turning discarded paper into valuable trays, it offers businesses a profitable and sustainable investment. This machine not only enhances efficiency but also supports green production practices that align with today’s environmental standards.

Factory scene

FAQ

What are the main products of our company?

Zhengzhou Miqi Machinery Equipment Co., Ltd. has a professional R&D team dedicated to the research and innovation of egg tray machines, egg tray production lines, pulp molding production lines, industrial packaging, tableware packaging, and automatic packaging machines. With years of theoretical and practical experience, we provide customers with comprehensive after-sales service.

Packaging system

The dried egg trays are sent through an automatic collection machine, counted, then compressed by a packaging machine, and finally packaged onto trays. This results in space savings and improved transportation convenience.

Metal drying system

The drying cabinet is linked to the molding machine. The wet trays are transferred to the drying cabinet for drying. The insulation layer is made of high-density mineral insulation cotton. The drying room has six layers, and the drying time is approximately 17-18 minutes. The uniquely designed circulating fan and automatic dehumidification system drive the hot air to circulate, removing moisture and drying the trays. This not only improves the drying efficiency but also reduces labor costs.

Brick kiln drying

The brick drying kiln has only one layer and is 60-80 meters long. The length may vary depending on the production volume. The formed egg trays are conveyed into the kiln through a mesh belt. The temperature should be controlled between 180-220 degrees. After about 20 minutes, the egg trays come out dry.

Model 6-8 Egg Tray Machine

Category:

TAG:

Get A Quote

Note: Please leave your contact information and our professionals will contact you as soon as possible!