Mainly suitable for automatic quantitative packaging of various mixed material briquettes, biomass pellets (refractory castable), granular material (feed, quartz sand), organic fertilizer, powder and granules, mixed materials, ice cubes, flaky (caustic soda flakes), bulk materials and irregular materials/refractory materials.

1、The machine mainly consists of five parts: feeding device, automatic weighing device, conveying device, sewing device, and computer control. Features reasonable structure, beautiful appearance, stable operation, energy-saving, easy operation, and accurate weighing. The host adopts fast, medium, and slow three-speed feeding, full touch screen computer, intuitive interface, Chinese display, simple and easy-to-understand operation.

2、The machine adopts two sets of weighing and measuring systems and feeding systems, alternating discharge, faster speed.

3、The pneumatic control components adopt the domestic top-end AirTAC brand.

4、control, stable signal transmission, ensuring weighing accuracy.

5、Belt feeding, no extrusion damage to materials.

6、The host adopts fast, medium, and slow three-speed feeding, inverter control, ensuring measurement accuracy and speed.

7、Equipped with slow feeding layer control and anti-leakage function to improve measurement accuracy.

8、The host, conveyor, sewing machine, and controller are networked to ensure user-friendly operation and reduce labor intensity.

Factory scene

FAQ

What are the main products of our company?

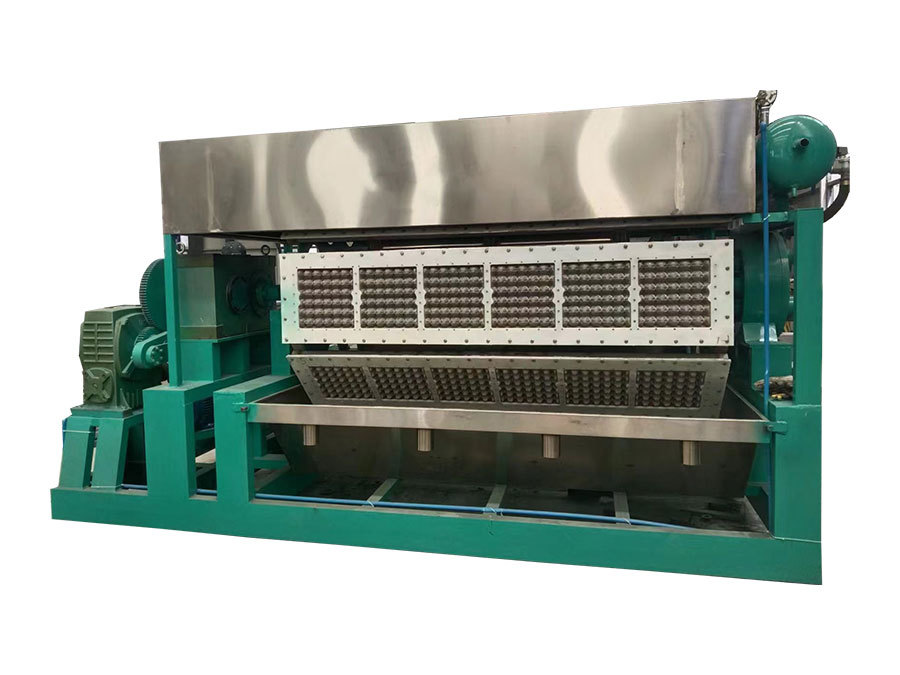

Zhengzhou Miqi Machinery Equipment Co., Ltd. has a professional R&D team dedicated to the research and innovation of egg tray machines, egg tray production lines, pulp molding production lines, industrial packaging, tableware packaging, and automatic packaging machines. With years of theoretical and practical experience, we provide customers with comprehensive after-sales service.

Packaging system

The dried egg trays are sent through an automatic collection machine, counted, then compressed by a packaging machine, and finally packaged onto trays. This results in space savings and improved transportation convenience.

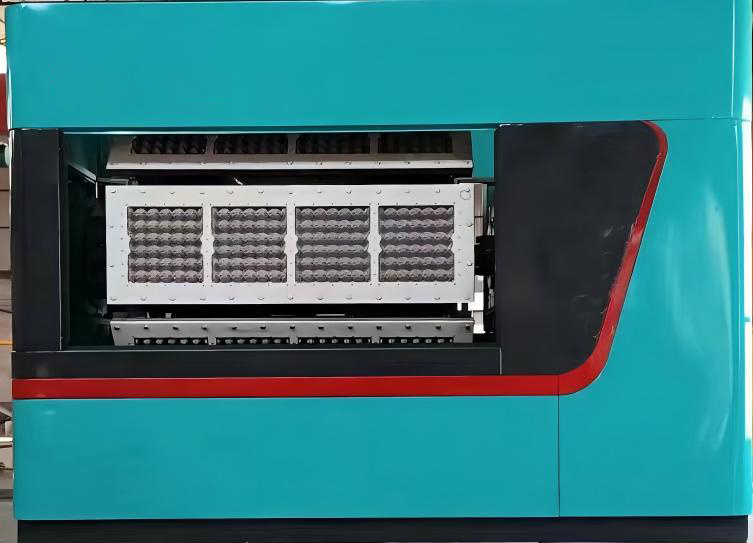

Metal drying system

The drying cabinet is linked to the molding machine. The wet trays are transferred to the drying cabinet for drying. The insulation layer is made of high-density mineral insulation cotton. The drying room has six layers, and the drying time is approximately 17-18 minutes. The uniquely designed circulating fan and automatic dehumidification system drive the hot air to circulate, removing moisture and drying the trays. This not only improves the drying efficiency but also reduces labor costs.

Brick kiln drying

The brick drying kiln has only one layer and is 60-80 meters long. The length may vary depending on the production volume. The formed egg trays are conveyed into the kiln through a mesh belt. The temperature should be controlled between 180-220 degrees. After about 20 minutes, the egg trays come out dry.

Belt Dual-hopper Quantitative Packaging Machine ZZ-50kg-PD2

Category:

TAG:

Get A Quote

Note: Please leave your contact information and our professionals will contact you as soon as possible!