Mainly for automatic quantitative packaging of grains like rice, millet, corn, and wheat.

1、Integrated design allows mobile operation indoors and outdoors.

2、Single-operator workflow: Manual bag placement only, with auto-clamping, conveying, sewing, and thread-cutting. Labor-saving and reduced labor costs

3、High speed and precision. Three-speed gravity feeding (high, medium, low) with customizable feed rates

4、Dual weighing hopper design achieves faster packaging speed (8-12 bags per minute).

5、Control computer uses premium domestic brands. Intuitive interface requires minimal operator training, with each action freely adjustable

6、Major components use reputable domestic brands for stable operation and low failure rate.

7、Cylinders adopt externally mounted imported oil seal design, suitable for high-dust environments with ultra-low failure rate

8、System auto-records shift, daily, and cumulative production data.

9、Optional automatic thread-cutting for sewing machine.

Factory scene

FAQ

What are the main products of our company?

Zhengzhou Miqi Machinery Equipment Co., Ltd. has a professional R&D team dedicated to the research and innovation of egg tray machines, egg tray production lines, pulp molding production lines, industrial packaging, tableware packaging, and automatic packaging machines. With years of theoretical and practical experience, we provide customers with comprehensive after-sales service.

Packaging system

The dried egg trays are sent through an automatic collection machine, counted, then compressed by a packaging machine, and finally packaged onto trays. This results in space savings and improved transportation convenience.

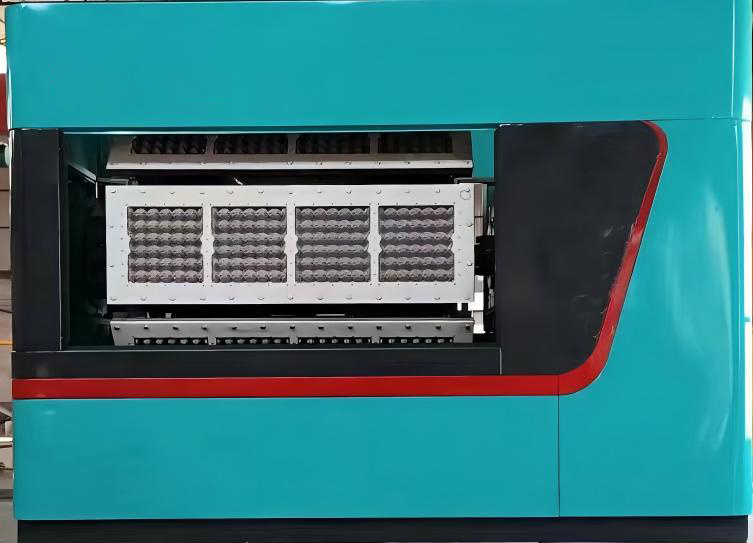

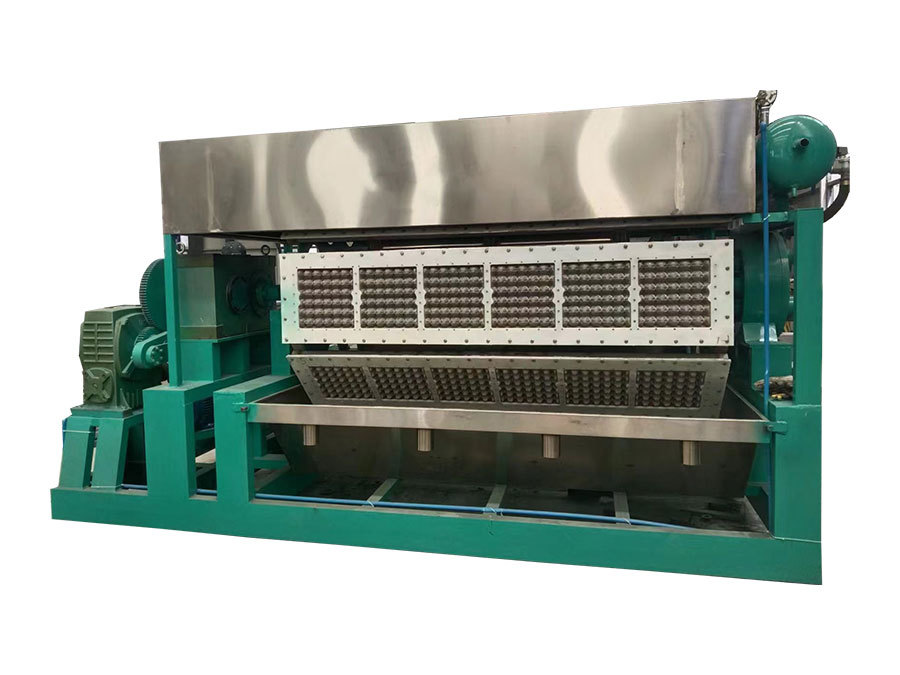

Metal drying system

The drying cabinet is linked to the molding machine. The wet trays are transferred to the drying cabinet for drying. The insulation layer is made of high-density mineral insulation cotton. The drying room has six layers, and the drying time is approximately 17-18 minutes. The uniquely designed circulating fan and automatic dehumidification system drive the hot air to circulate, removing moisture and drying the trays. This not only improves the drying efficiency but also reduces labor costs.

Brick kiln drying

The brick drying kiln has only one layer and is 60-80 meters long. The length may vary depending on the production volume. The formed egg trays are conveyed into the kiln through a mesh belt. The temperature should be controlled between 180-220 degrees. After about 20 minutes, the egg trays come out dry.

Dual-hopper Scale for Granules (Single-operator). ZZ-60kg-ZDZL

Category:

TAG:

Get A Quote

Note: Please leave your contact information and our professionals will contact you as soon as possible!